What is TOM?

|

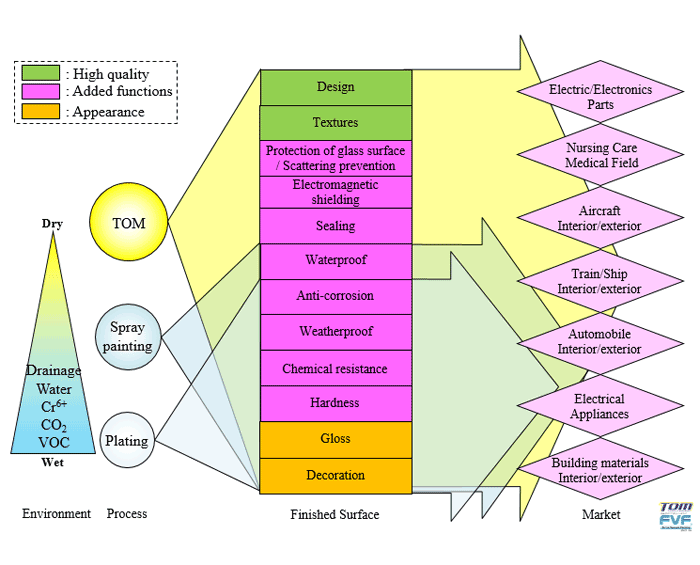

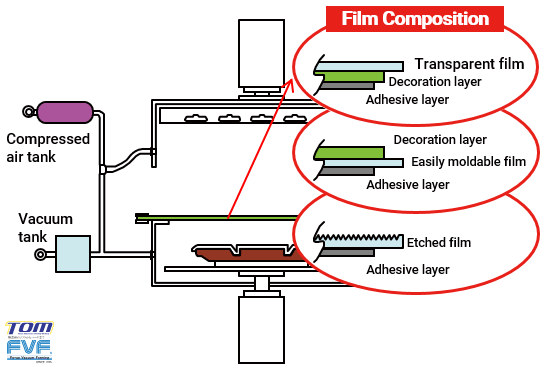

TOM thermoforming NGF developed into TOM as 3D surface decoration forming.By TOM, overlaying with skin-material or transfer printing can directly be performed onto a substrate (product) which replaces a mold. By using film with high functionality, a product can be sealed, waterproofed, or made antifouling. |

||

Video - Introduction to TOM thermoforming machine

| NGF rotary machine with two forming stages | |||

| NGF shuttle machine with a single forming stage |

How it works ?

|

|

||

|

||

|

|

||

|

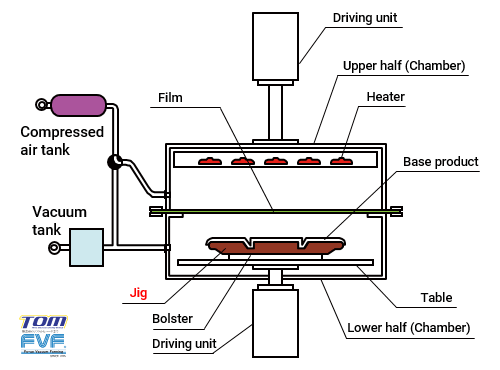

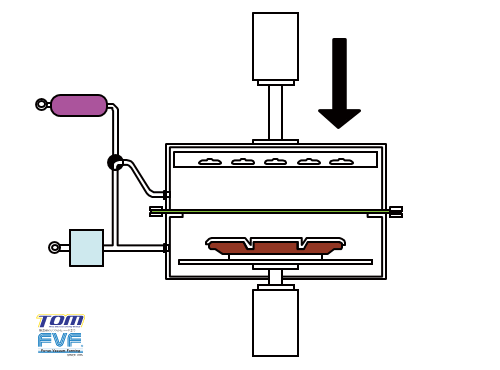

Base product and

Film in place 1. Set the base material (product) on the table. 2. Set the skin-material (Decoration Film). 3. Both upper and lower halves of the chamber at atmospheric pressure. |

|

|

|

||

|

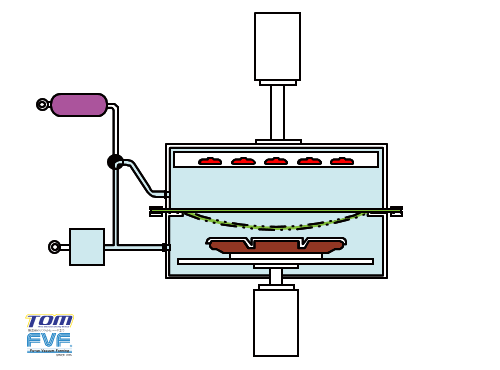

1. Upper half lowered, and the entire chamber becomes airtight. 2. The inside of the chamber is still at atmospheric pressure. 3. Two spaces divided by the decoration film. |

|

|

|

||

|

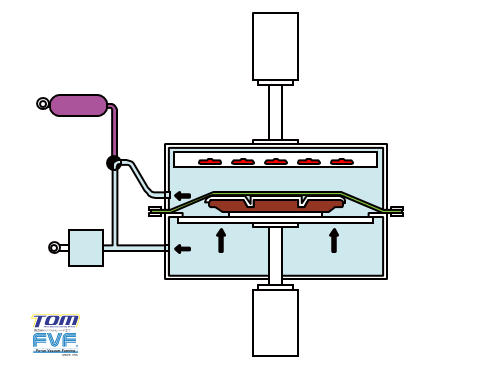

1. The inside of the chamber (both upper and lower halves) made vacuum. 2. Heater turned on to heat the skin material (Decoration Film). 3. The radiant heat softens the film. 4. The heated sheet-material softens and sags; however, it is always held horizontally because a slight difference in pressure between the upper half and the lower counterbalances its gravitational weight. |

|

|

|

||

|

1. The table in the lower half moved upward 2. The inside of the chamber (both upper and lower halves) is vacuum. |

|

|

|

||

|

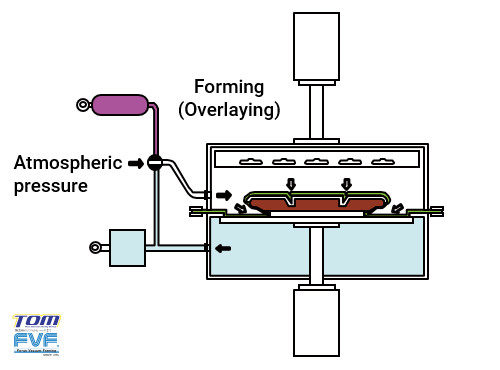

The skin-material is firmly pressed on the substrate (product) due to the pressure of the atmospheric air released into the upper half, and the overlay is completed. |

|

|

|

||

|

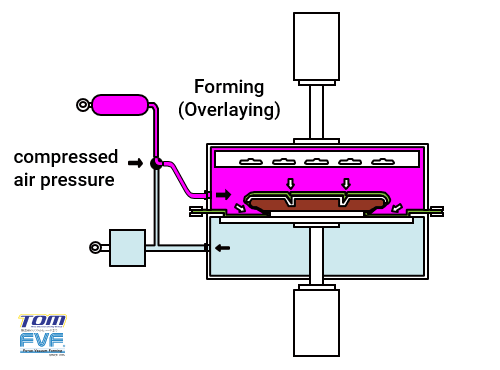

Compressed air is used if necessary. The skin-material is more firmly pressed on the substrate (product) by the compressed air released into the upper half than atmospheric air. (Thermal transfer printing) |

|

|

|

||

|

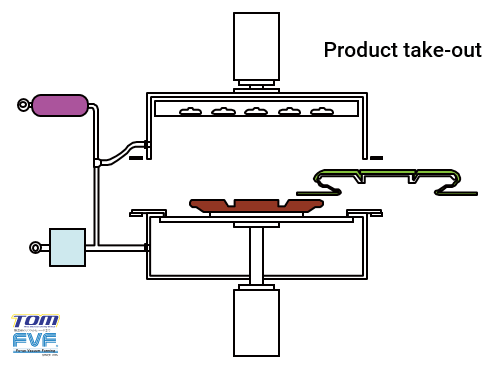

1. Atmospheric air is released into both the upper and lower halves. 2. Upper half is slightly made vacuum for the mold to be released easily. 3. Atmospheric air is released into the upper half again, and it is moved upward to remove the thermoformed product. |

|

|

|

||

|

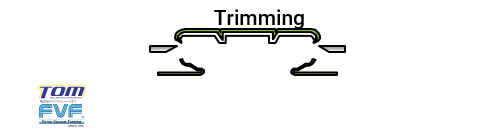

Unnecessary skin material parts are hand-cut or trimmed with a laser trimming machine. |

|

Examples of adopted products

Bathroom vanity door panels (overlaid with wood grain film by TOM thermoforming) |

||||

|

|

|

|

|

| Substrate (product) | after thermoforming by TOM | available on the market | ||

Electronic organ (an injection molded component overlaid with wood grain film by TOM thermoforming) |

||||

|

|

|

|

|

| Substrate (product) | after thermoforming by TOM | available on the market | ||

Nursing care bed (a blow molded component overlaid with wood grain film by TOM thermoforming) |

||||

|

|

|

|

|

| Substrate (product) | after thermoforming by TOM | available on the market | ||

Automobile parts (overlaid with clear/translucent chrome looking film by TOM thermoforming; adopted as lighting parts thanks to the clarity of the film) |

||||

|

|

|

|

|

| Substrate (product) | after thermoforming by TOM | Assy state | ||

|

||||||

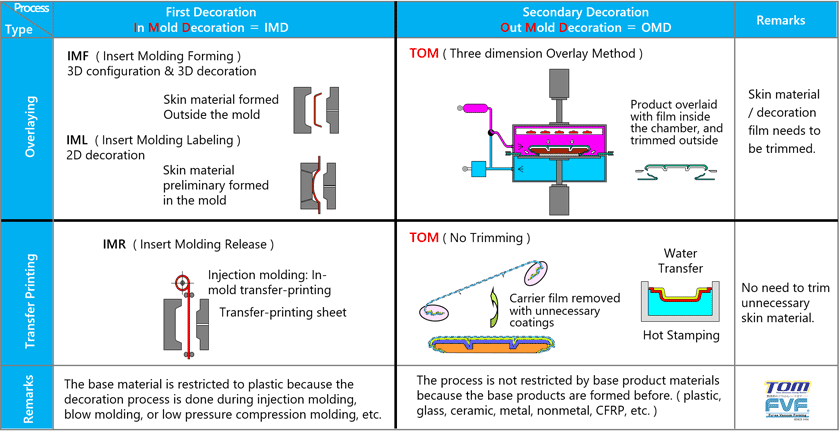

Categorization of 3D thermoplastic film decoration technologies

Overlay and Transfer

![]() What is overlay...

What is overlay...

‘Overlay’ is a decoration method in which film overlaying a substrate (product) remains on it after TOM thermoforming except for the film trimmed around the edges. The film enhances the product appearance with its originality.

![]() What is Transfer...

What is Transfer...

‘Transfer’ is a decoration method in which the film is peeled after TOM thermoforming from the substrate (product), and only the decoration layer remains on it; therefore, no trimming is necessary. A protective hard coating layer as well as a decoration layer can be transferred to the product.

|

||||||||||

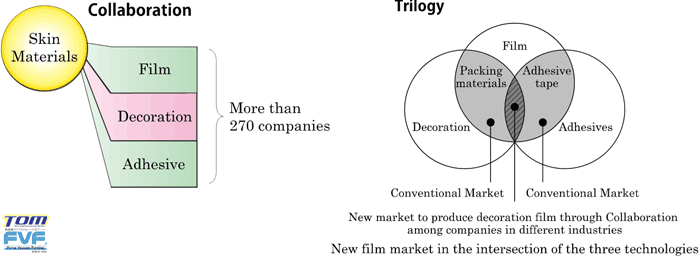

Market vitalized by TOM and its potential