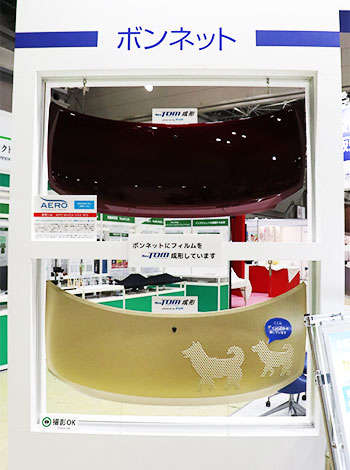

TOM has developed into Neo-TOM to decorate extremely large products such as automobile bodies.

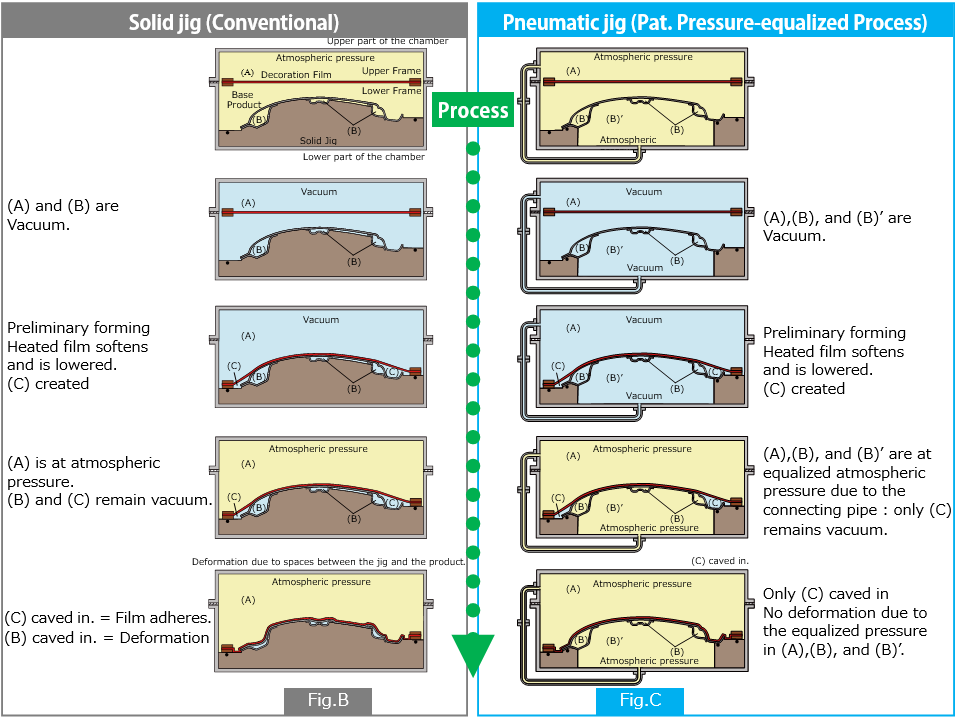

The most significant feature is that a structurally complicated substrate (product), such as one with hollows, can be overlaid with

skin-material without any deformation by using a pneumatic jig instead

of a conventional solid one.

(Pat. Pressure-equalized Forming Process)

Neo-TOM Features with all TOM features maintained

(1) Although a substrate (product) is extremely large, it is firmly set

in place, and film (skin-material) is moved down toward

the substrate (product), which results in the weight reduction of the entire

machine. (Pat.)

(2) Even a substrate (product) whose reverse side is structurally complicated is firmly fixed by the jig which utilizes air. (Pat.)

Images of Neo-TOM Machine and its Operation

Neo-TOM process is shown in Figure 12, in which a car is loaded into the machine, overlaid with thermoforming film, and unloaded. This process is meant to be for small vehicles; however, it can easily be adapted for large vehicles by changing the machine dimensions.

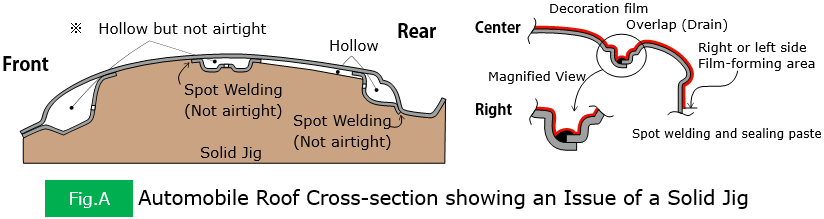

Solution to Automobile Body Structural Problem

| Solution to Automobile Body Structural Problem Regardless of what material

to be used, an automobile body is made of thin plates; therefore, in order

to reinforce it, ribs are attached, creating hollows as shown in Figure

A. These empty spaces, as well as the body’s poor precision in dimension,

don’t make it possible for a conventional jig to contact the body’s inside

completely, which is likely to cause deformation during the thermoforming

process shown in Figure B. In order to solve this problem, a new type of

jig, called Pneumatic Jig, has been devised, as shown in Figure C. |

|

|

|

|

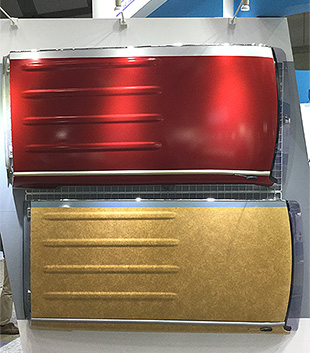

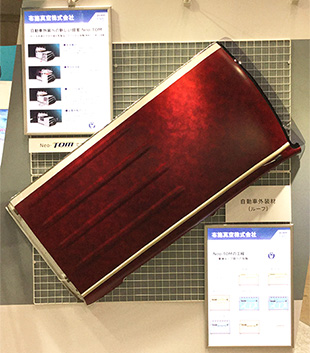

The technological innovation replaces the wet automobile painting process with the dry one.

Replacing a paint process with decoration film overlay for two-tone automobile

bodies

Replacing a paint process with decoration film overlay for two-tone automobile

bodies

Diversification in exterior decoration

(1) Overlaying with high thermal insulation skin-material makes the

temperature inside the car stable, reducing the power consumption of the

air

conditioner.

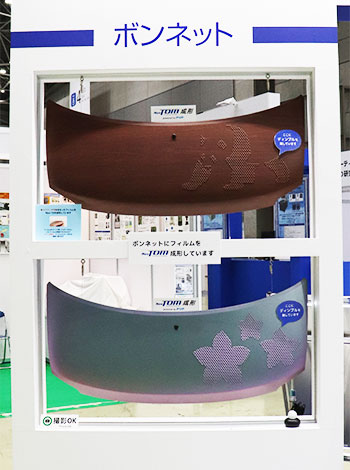

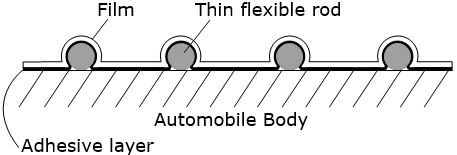

(2) Overlaying an automobile body with a combination of film and thin

flexible rods, making streamlines, improves the automobile aerodynamics

and

results in better gas mileage.

Automobile surface cross-section

(A combination of film and thin flexible rods) |

|

A one quarter scale automobile body overlaid with

a combination of film and thin flexible rods. |

|

|

|

|

|

Besides TOM key features, Neo-TOM has the following additional features:

(1) Although a base product, such as an automobile, is large and heavy,

it remains at the same position during the process where

the decoration film is moved toward the base product, which makes it possible

to reduce the Neo-TOM machine’s weight. (Pat.)

(2) Pneumatic Jig makes it possible to decorate a base product even with complicated contours and hollows. (Pat.)

(3) Adding to TOM the capability to decorate large base products with complicated

contours and hollows, Neo-TOM can create and

expand various markets, which can be installed in automobile assembly

lines.

The parties to “The United Nations Framework Convention on Climate Change” (UNFCCC) met in “Conference of the Parties” in Paris in 2015 (COP21) and adopted the Paris Agreement to be signed in 2016 to set a goal of limiting global warming. It hasn’t been more important nowadays to reduce VOCs (volatile organic compounds), hexavalent chromium, etc. as well as CO2 emissions to make our manufacturing processes environmentally friendly.

Today 3D surface decoration is mostly done by spray painting or chrome plating; the former process releases VOCs in the surrounding air, and the latter leaves hexavalent chromium in its drainage water. There is no such problem with TOM/Neo-TOM as an alternative dry process.

In addition, TOM and Neo-TOM can add to products not only great decoration but also great functions to make them thermally insulated, weatherproof, chemically resistant, suitable used with some electromagnetic waves, etc., by overlaying them with film which has such properties, and we really expect that TOM/Neo-TOM becomes a new core technology in various markets much sooner than we think.

![]() Replacing a paint process with decoration film overlay for two-tone automobile

bodies

Replacing a paint process with decoration film overlay for two-tone automobile

bodies